5

Timeline

Hydraform constructs the

upmarket Mc Nellie housing estate

in Johannesburg retailing for

over $300K per unit.

In answer to our clients looking for

a reliable, robust conventional brick

and paving machine, the range of

conventional brickmaking machines

was launched delivering a variety

of blocks from hollow blocks and

pavers to ribbon and retaining

blocks.

Hydraform introduces the tile

machine to the range for the

production of extruded concrete

roof tiles.

The M7MI-Super and the M7MI-Twin

Super which increases production

output by 45% and other features to

improve block production.

Introduction of the M9 semi-manual

entry level machine with production

of just 500blocks/day.

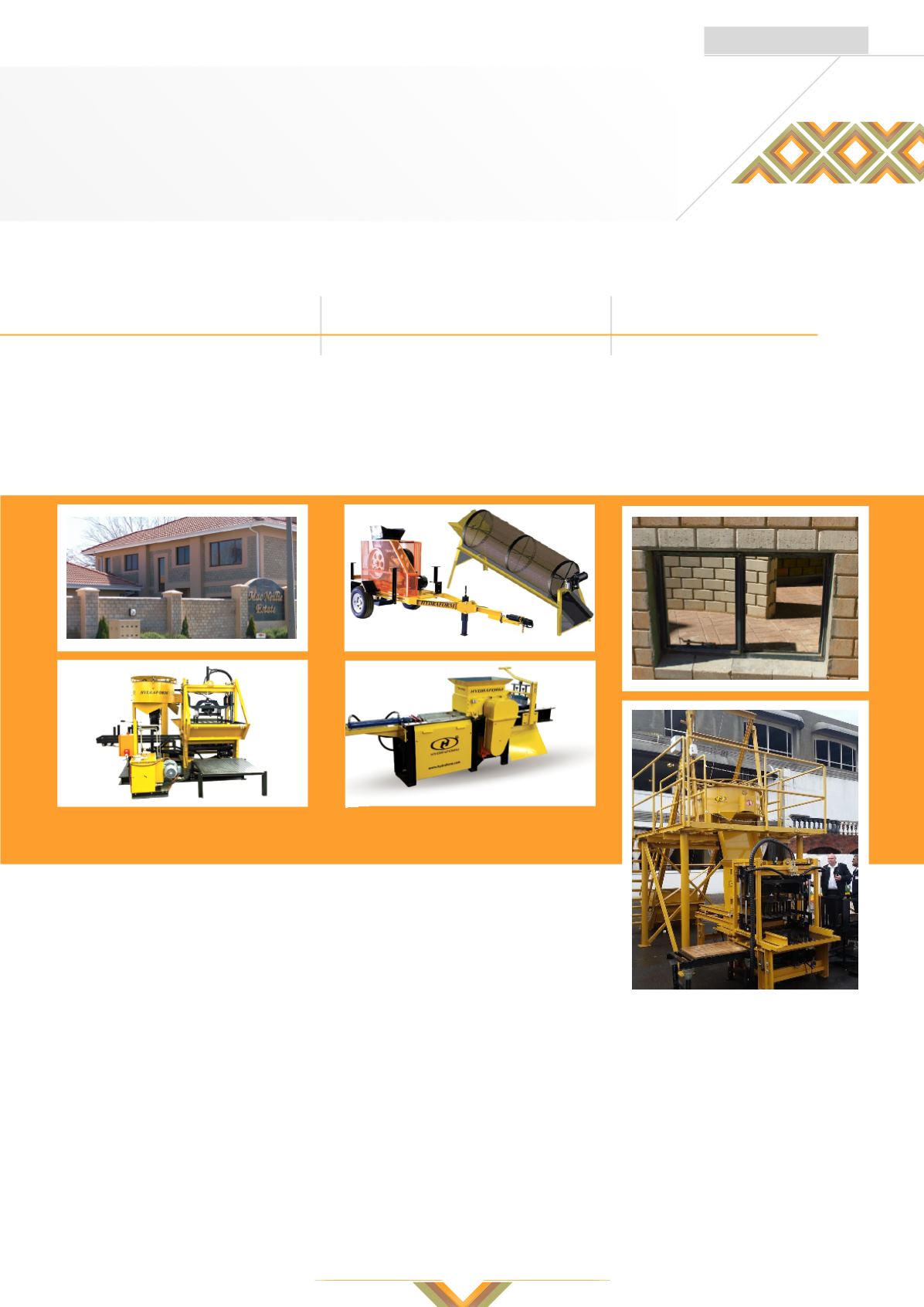

Accessories products, rotary sieve

and jaw crusher were added to

compliment block production.

Automation of Hydraform

machines for increased

production and safety.

The 2015 product launch saw the

introduction of three new lines,

the M7A2, Lintel Mould and V4.

The M7A2 and V4 machines

increased production significantly

and reduced labour to make

block production even more

cost effective.

Hydraform’s conventional brick

machines produce hollow

blocks, stock bricks, maxi blocks,

retaining blocks, interlocking

paving slabs and rectangular

paving slabs.

Hydraform’s accessory products:

the Jaw Crusher (left) the Rotary

Sieve (right).

Hydraform’s TM-1000 (bottom)

uses aggregate to make

extruded concrete roof tiles in a

variety of shapes and sizes.

The Hydraform Lintel is designed

to look like the interlocking

blocks while also interlock into

the Hydraform soil-cement

blocks used in the walls.

2006 - 2010

2011 - 2014

2015

THE YEARS