13

Oriental Odyssey

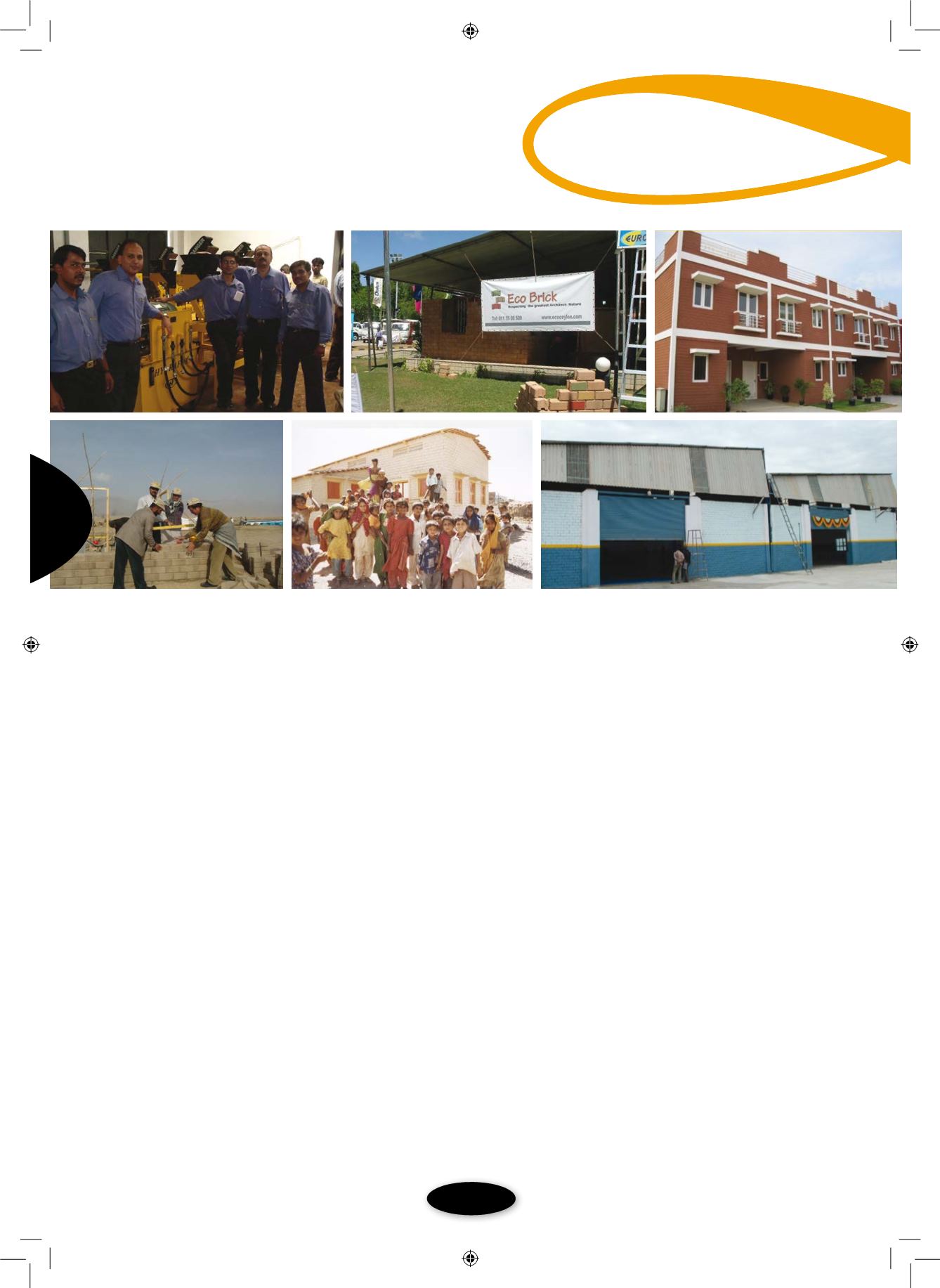

The eventual goal of the new company was to expand

the reach of the company’s products and services to

cover the entire sub-continent. As with anything new,

it was tough going at first but gradually Hydraform’s

interlocking technology started gaining acceptance

and today the company has a wide presence in the

region.

Naturally customisation to better suit local conditions

is an important part of any expansion programme.

Accordingly, Hydraform India needed to customise the

product and application thereof to meet the requirements

of the local building industry.

The initial focus of the Indian operation was to provide

the country’s government with a robust, reliable and

cost-effective social housing solution that could be

deployed quickly and effectively wherever needed. As

such, Hydraform technology quickly became the preferred

solution for social sector initiatives such as post-disaster

rehabilitation and shelter programmes, mass housing

projects and employment generation, as well as in social

or economic empowerment programmes instituted by aid

agencies and government.

Among the many rehabilitation projects that have

successfully used Hydraform machines, technology and

training are:

• the earthquake rehabilitation project in Gujarat

• the cyclone rehabilitation project in Orissa

• tsunami rehabilitation projects in South India and

Sri Lanka

• shelter programmes in Sri Lanka

• flood rehabilitation and shelter programmes in Barmer

• the flash flood rehabilitation project in Leh

• a host of other initiatives focused on employment,

skills development or resettlement.

In the course of all of this humanitarian activity,

Hydraform building technology and machines have been

chosen by prestigious multinational institutions such

as UNDP, Action Aid, Tata Relief, CARE, HUDCO and

BMTPC. Similarly, many large local corporates have

selected the machines for use in their own corporate

social responsibility initiatives.

Collaboration and growth

Of course, this hasn’t occurred in a vacuum. As is the

case all over the world, the company always works

closely with communities, housing technology institutions,

building materials technology councils, architects,

engineers, professionals and artisans to ensure that

building materials produced by Hydraform machines are

of the highest quality and meet the most stringent quality

standards.

The nett result of these efforts in India saw something

that began life primarily as a social housing solution

develop into a widely accepted and viable alternative

now extensively used in the mainstream construction

sector. Hydraform technology has been used in practically

all types of construction projects: from cluster-housing

to multi-storey housing developments, from industrial

facilities to schools and colleges, from offices and

warehouses to boundary walls around business parks or

residential developments.

One of the most compelling factors – certainly where the

international aid agencies are concerned – is Hydraform’s

capacity to meet green building standards. Although the

existing soil-cement blocks are among the most carbon-

neutral building materials available today, the company

has gone the extra mile by developing solutions involving

the use of post-industrial and -agricultural waste as well as

fly-ash in the construction of its blocks.

At the time of its 25th anniversary, there were well over

400 Hydraform machines working in the sub-continent

and across southern Asia. More up-to-date information is

available on

www.hydraformasia.comHydraform3.indd 13

6/18/13 11:39 AM