Building Technology

For hundreds of years there has been little revolution

in the construction industry in terms of design

and materials. As Professor Mitch Gohnert of the

University of Witwatersrand (WITS) states, “to change

the way we build we need to consider both the design

and materials”. WITS masters student Vanja Bulovic

took these words to heart and decided to do her

thesis on sustainable low-cost housing with different

materials and not necessarily using conventional

designs.

Since some 30% of the building cost in standard houses

is spent on the roofing structure, which does not add to

living space, Bulovic theorised that it would be possible

to reduce the cost by also using roofing space for living

space. This led her to designs featuring an inverted

catenary curve to produce a curved roof that holds its

own weight under perfect compression.

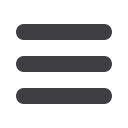

In practice she was able to produce the design by using

Hydraform interlocking blocks. This resulted in still more

cost savings through the shorter construction time and only

needing mortar in 30% of the structure. The Hydraform

splitter brick was then used to build the curved roof structure.

The house Bulovic constructed at WITS has an area of

around 75m

2

– almost double that offered by current low-

cost housing. As it stands, and without factoring in labour

and finishings, the dwelling cost just under US $10 000

to construct. The dwelling is being tested for thermal

efficiency and is expected to perform significantly better

than conventional brick-and-mortar structures.

Hydraform’s hope is that, once fully tested, the WITS

Hydraform house can be replicated in any developing

country. Further cost advantages could be gained by

involving communities in the production of blocks and

construction, thereby also creating jobs.

The future of

construction?

To build a sustainable future, we need new and

innovative methods of construction in developing

nations. Hydraform may have the answer.

14