27

Case Study: Tanzania

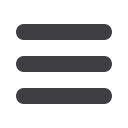

As part of NHC’s efforts to fulfil its mandate, it

awarded local Hydraform partner Newton Trust the

Kibada project in Dar es Salaam. As a result, some

180 houses have been built using Hydraform

technology at a reported cost savings of 30% on

what would have been the price had conventional

brick and mortar systems been used.

The Kibada project is also the first green housing

project undertaken in Tanzania. Using the Hydraform

system, soil from the local area was used to manufacture

blocks on site. Blocks are cured in the sun rather than

being baked – resulting in significant energy savings

in their manufacture – and producing blocks at the

building site virtually eliminates transport costs (and the

associated fuel emissions) from the equation.

NHC has also used special airflow systems in the

houses to improve cooling, thereby minimising the

energy required for cooling by the inhabitants. Other

benefits include lower construction costs, higher

strengths, faster construction and the creation of

employment around the various sites.

Subsequently, NHC has procured 15 of its own Hydraform

blockmaking machines, each of which can produce 2 000

bricks per day, translating to enough blocks to build a single

85m

2

house every week. The machines have been deployed

at 10 ongoing affordable housing projects.

Delivering

green housing

National Housing Corporation (NHC) Tanzania is responsible

for affordable quality housing delivery in that country.