Building Machines

Foundation

of an industry

The fundamental building blocks of Hydraform’s building system

are the machines that produce the soil-cement blocks and tiles.

Over the past quarter-century, the reliability and

robust construction of the various models of

Hydraform blockmaking equipment has become

legendary – to the extent that numerous anecdotal

stories have grown around this over the years.

Perhaps the most representative tale is the one

involving a Hydraform blockmaking machine originally

sold in 1992 and discovered rusting on a farm in Zambia;

after Hydraform staff flew in to service it and provide

training, it was back in action producing soil-cement

blocks in a matter of weeks. Hydraform is well aware

that, in the field, its machines can often be subjected to

the harshest of climatic conditions imaginable. The

machines it builds and sends into the wide blue yonder

must be capable of withstanding tough conditions and

operating with only basic servicing for long periods

of time.

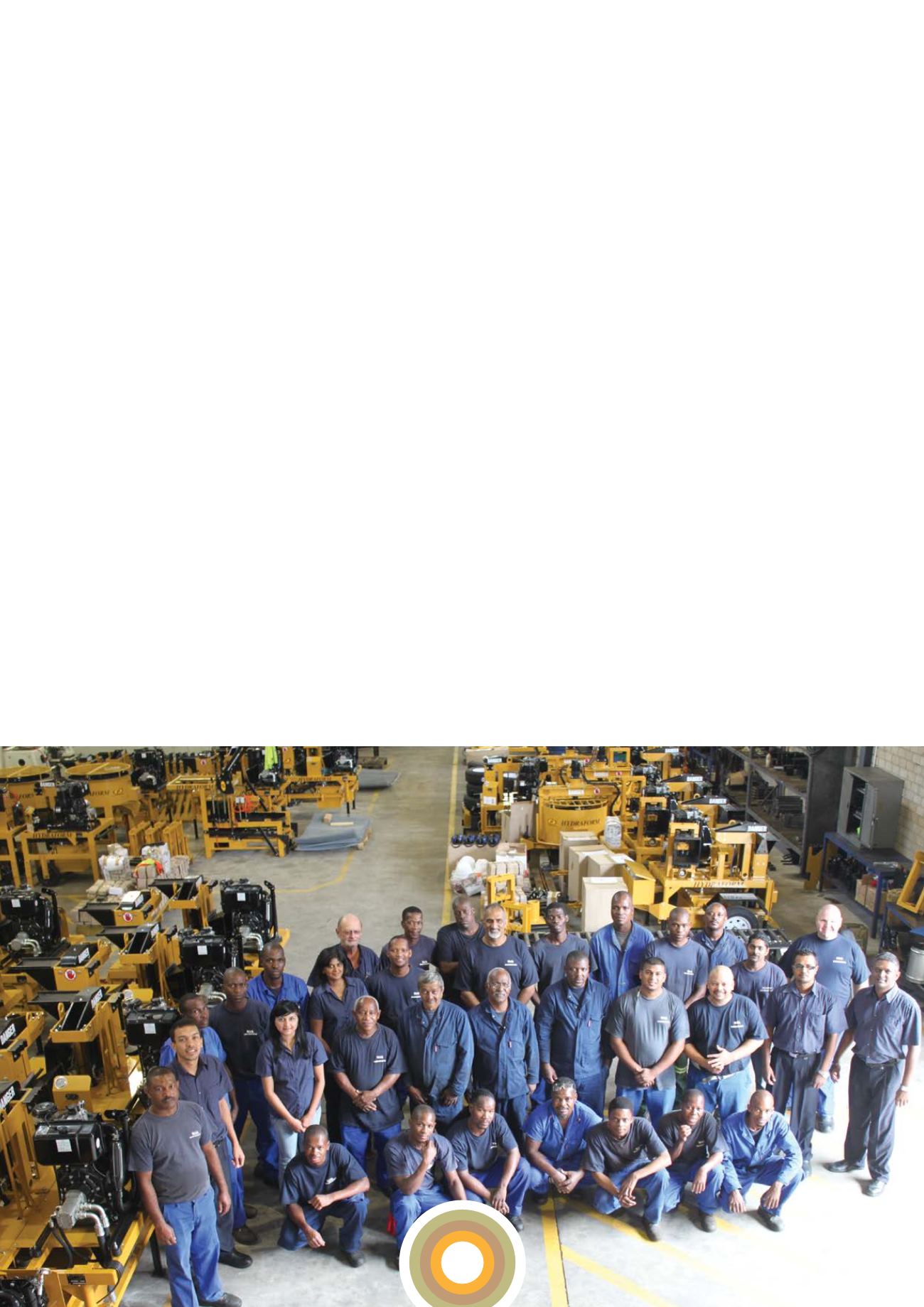

A matter of pride

Such reliability doesn’t happen by accident. It begins with

a robust and forgiving design and ends with the choice of

solid materials with which to manufacture the machines.

Effective and efficient manufacturing processes must also

be followed to continue to produce the machines that are

now found in over 50 countries around the world.

And apart from the renowned blockmaking machines,

the Hydraform factory manufactures a range of

conventional construction machinery, including pan mixers

and conventional egg-layer and static block, brick and

paving machines. In all cases, the same design principles

coupled with the highest-quality materials and top-quality

workmanship are standard.

Precision engineering ensures each machine is made to

last and all the individual parts are given a dual-coat spray

finish before assembly. Quality management ensures

every machine is checked during actual block production,

thoroughly tested and finally given the green light before

dispatch.

Furthermore, the factory itself has specifically been

designed to be flexible enough to scale production up or

down at a moment’s notice. But perhaps most important

of all is the immense pride that Hydraform’s manufacturing

staff take in their work. They revel in the rapidly growing

body of anecdotal tales of Hydraform machines still

operating after 20 or 25 years, or being brought back into

full production in a matter of weeks after being neglected

for years or even decades.

Perhaps most important of all is the immense pride that

Hydraform’s manufacturing staff take in their work.

35