29

Case Study: Africa

Uganda

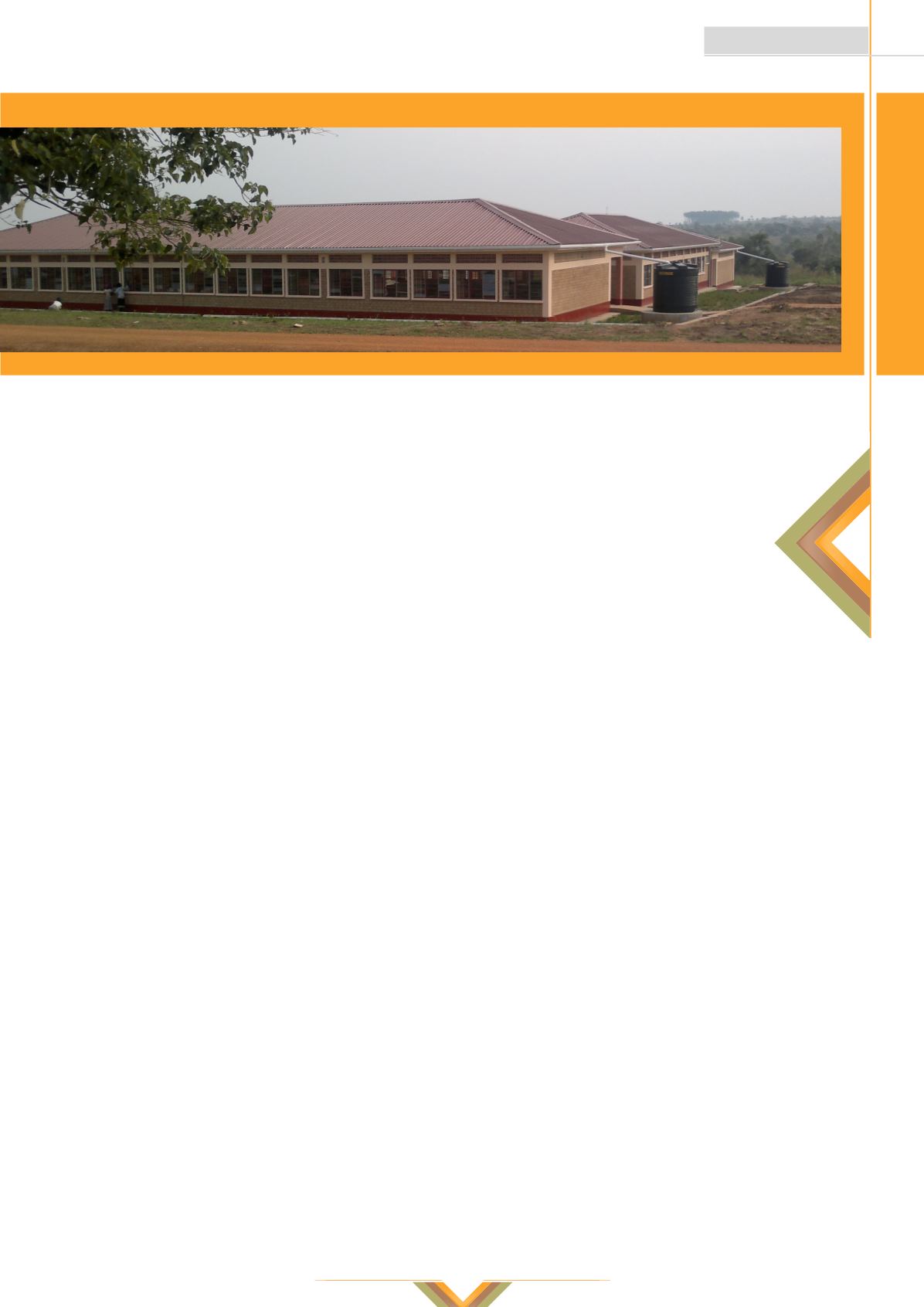

The secondary school being developed in northern Uganda by the Society of Jesus has

come some way since we first reported on it.

Furthering Africa’s

Education

T

he Ugandan chapter of the Society of Jesus is

developing and constructing a modern secondary

school located near the city of Gulu, some 355km

north of the country’s capital, Kampala. It’s a three-

phase project developed according to flow of funds

from various donors, which include foundations and

individuals in the USA, alumni of a college based in

Wisconsin, and a number of organisations in Europe.

The school has been designed to accommodate 1 200

boys and girls, drawing students from the entire region

and housing boarders. Also included in the plans are

faculty housing, a Jesuit residence and two convents for

sisters.

It is being built using the Hydraform Building System

(HBS) and is now in its final stages, withmajor infrastructure

completion expected by 2017. According to the Society,

HBS was chosen for its comparative cost advantage

over conventional building materials, its environmental

friendliness, and its cost-effectiveness.

An important factor that influenced the choice of

construction methodology was the need for the school

to be environmentally and culturally sensitive. Hydraform

soil cement blocks fit that profile because there is no

need to cut down trees for burning in the curing process

– that is accomplished with a combination of water and

sunlight.

The main beneficiaries of the project are communities

in northern Uganda, mainly the Acholi sub-region. The

project employs around 100 regular workers, although

more than 500 have been employed (both directly and

indirectly) since inception of the project.

In addition, along the way more than 100 youths have

been trained in block production, artisanal works, and

electrical, welding and metal fabrication.

After the project is completed, the school will retain

a small team that will continue to produce blocks for

vocational purposes for as long as the two machines last.

And, given the robust design of Hydraform machines,

this could be for another 20 years or more.