30

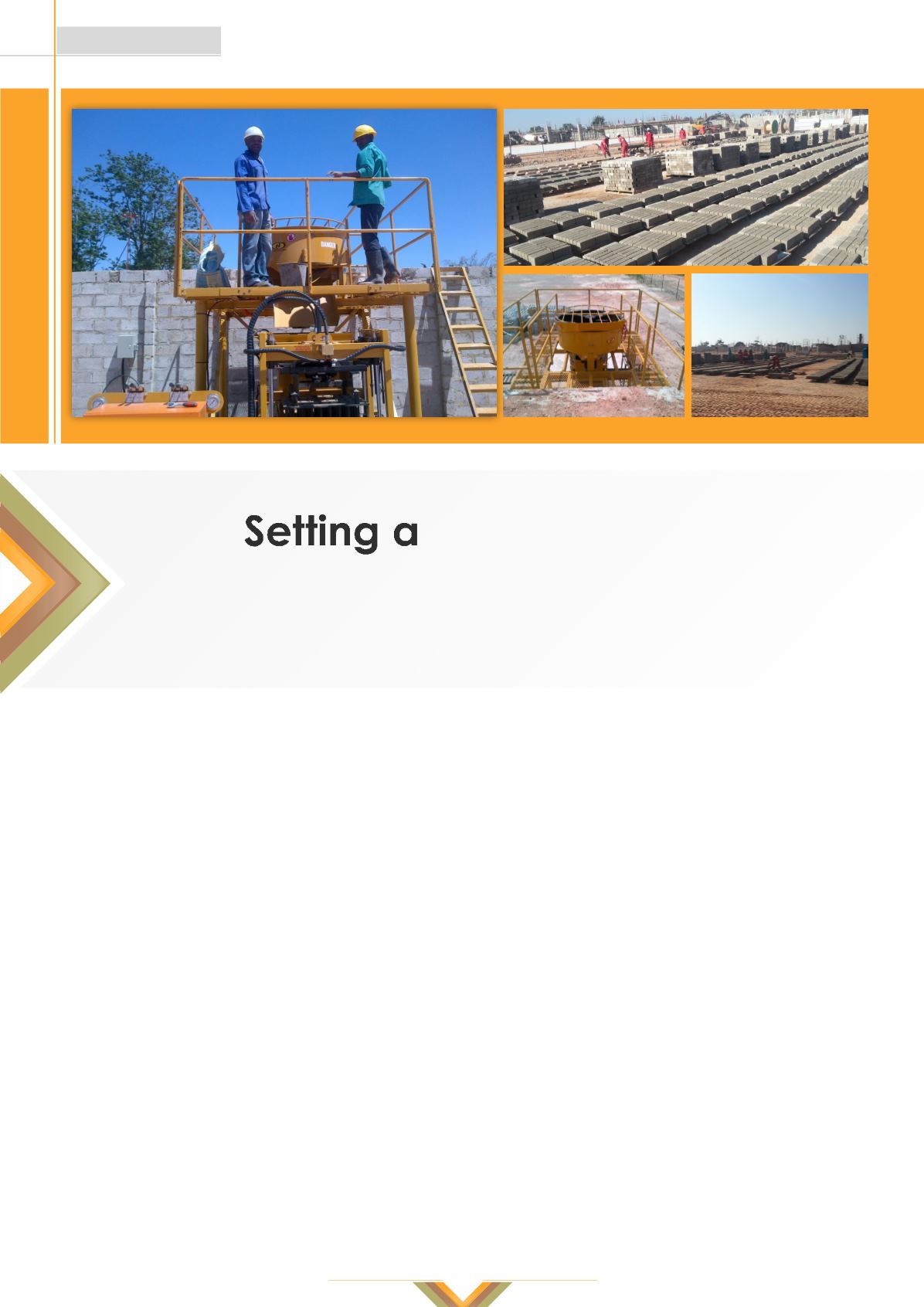

Case Study: Africa

Zambia

While most Hydraform clients are NGOs or governments looking for affordable, quality

building solutions, some clients are commercial operations that use the technology to

get a competitive edge. One such is Yo Limba Block & Bricks Limited.

for commercial success

Blockyard

A

ccording to MD Alistair McGlashan, Yo Limba

presently makes and sells 6-inch and 8-inch blocks, lintels,

bricks and pavers – all of which are manufactured on

its Hydraform V3 Hydraulic Conventional Brick machines.

The firm is also seriously considering manufacturing other

products for which it has the capability on their Hydraform

machines with a simple change of moulds. The company

uses a mix of quarry dust, quarry stone, Lafarge Supaset

and Chryso Chemical additives to produce their range

of cement products. “All our products are tested and

certified on an ongoing basis by the Lafarge Test Lab in

Chilanga, Lusaka,” says Alistair.

Yo Limba has enjoyed significant success in supplying

construction projects where the key is being able to meet

the demand for large orders. Where previously this may

have put a strain on Yo Limba’s resources, now, thanks

to the acquisition of the newly launched Hydraform V4

model, this is no longer a problem.

According to McGlashan, the new machine has

reduced the need for labour, increased production

volumes and, consequently, improved the businesses

margins. Indeed, a single V4 hydraulic paving- and

blockmaking machine requires only two operators and

can produce up to 15 000 stock bricks in a single day.

One Yo Limba project that is presently still in progress is

Makeni Mall, the largest shopping mall in Zambia, where

Yo Limba has been contracted to produce three million

blocks.

Another project recently completed involved the

production of 100 000 blocks, which were used to

construct a new hospital and clinic. A similar-sized project

for a Lusaka businessman saw Yo Limba manufacturing

another 100 000 blocks. These were used to build a

storage unit complex.

A potentially massive project for the BBATA Consortium

also called for production of 100 000 blocks. These were

used to build 10 show units for an affordable housing

development that is expected to comprise around 1 000

houses when completed.

There have been many other major projects over the

years, and from Alistair’s perspective, each new one

provides another reference site he can use. Business is

good in Zambia, he says – very good.