33

Hydraform Global

A

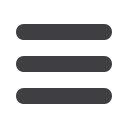

mong the many projects that have successfully used

Hydraform machines, technology and training in the

Indian subcontinent are:

• the earthquake rehabilitation project in Gujarat

• the cyclone rehabilitation project in Orissa

• tsunami rehabilitation projects in South India and

Sri Lanka

• shelter programmes in Sri Lanka

• flood rehabilitation and shelter programmes in Barmer

• the flash flood rehabilitation project in Leh

• a host of other initiatives focused on employment, skills

development or resettlement.

In the course of all of this humanitarian activity,

Hydraform building technology and machines have

been chosen by prestigious multinational institutions

such as UNDP, Action Aid, Tata Relief, CARE, HUDCO

and BMTPC. Similarly, many large local corporates have

selected the machines for use in their own corporate

social responsibility initiatives.

Collaboration and growth

Of course this hasn’t occurred in a vacuum. The

company always works closely with communities, housing

technology institutions, building materials technology

councils, architects, engineers, professionals and artisans

to ensure that building materials produced by Hydraform

machines are of the highest quality and meet the most

stringent quality standards.

The nett result of these efforts is that something that

began life primarily as a social housing solution soon

develop into a widely accepted and viable alternative

for mainstream construction. Hydraform technology

has been used in practically all types of construction

projects: from cluster housing to multi-storey housing

developments, from industrial facilities to schools and

colleges, from offices and warehouses to boundary walls

around business parks or residential developments.

One of the most compelling factors – certainly where

the international aid agencies are concerned – is

Hydraform’s capacity to meet green building standards.

Although the existing soil-cement blocks are among the

most carbon-neutral building materials available today,

the company has gone the extra mile by developing

solutions involving the use of post-industrial and

-agricultural waste as well as fly-ash in the construction

of its blocks.

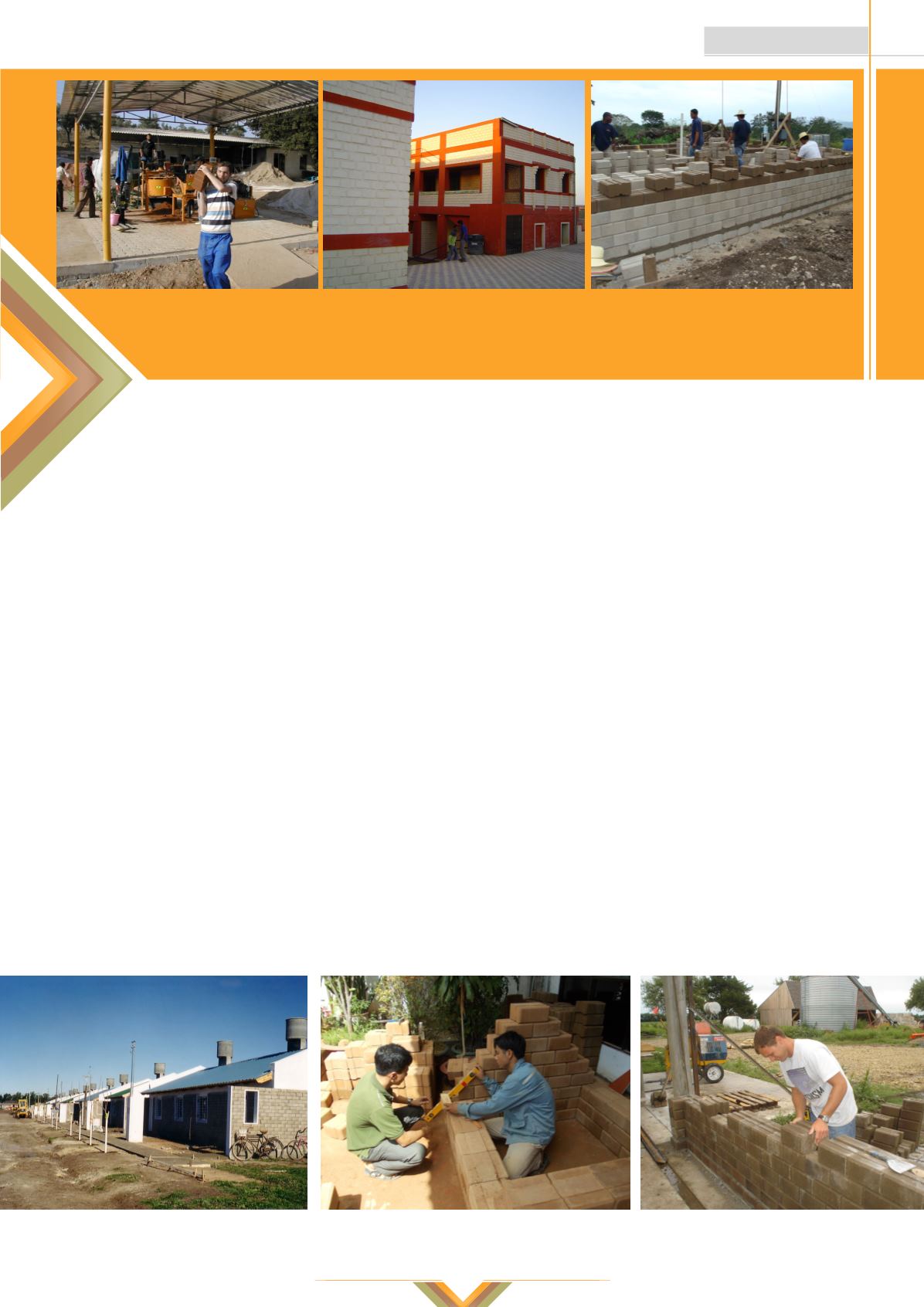

Today, after some 28 years of manufacturing Hydraform

blockmaking and tilemaking machines, there are more

than 4 000 such machines in operation at a wide range

of locations around the world. And that number is

increasing virtually on a daily basis.

India

Kansas, USA

Vietnam

Argentina

Turkey

Philippines